PROSorb is a new silica gel ideally suited for stabilizing relative humidity inside museum display cases and storage cabinets.

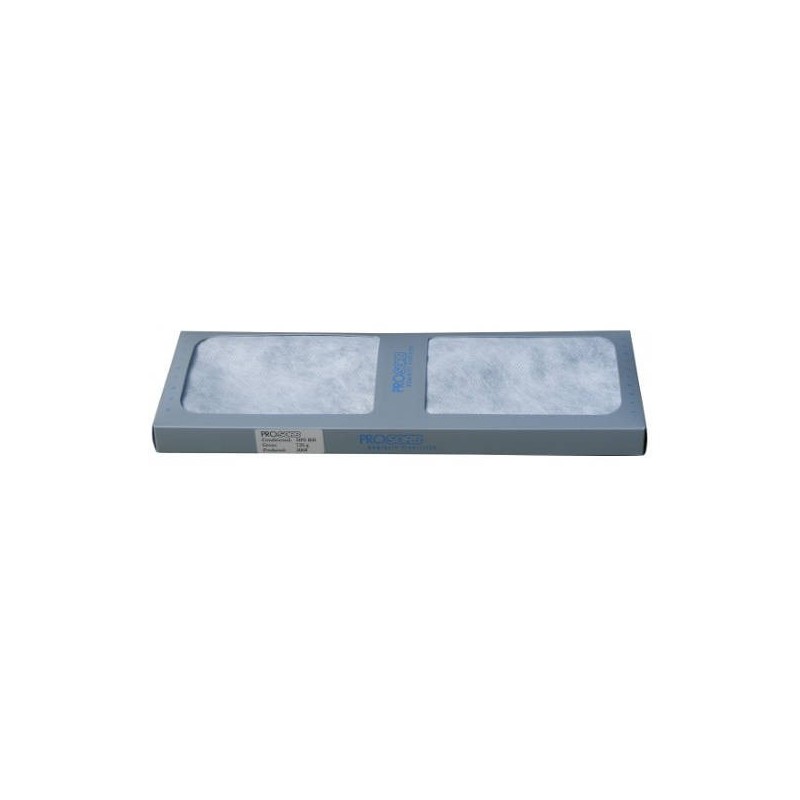

Available in 500 gr cassettes. 55% RH ready in stock

Other conditioning available on demand only. Lead time: 3-4 business days

Secure payments: PAYPAL, Credit card, Bank transfer.

Secure payments: PAYPAL, Credit card, Bank transfer.

need advice? contact us to find the correct product.

need advice? contact us to find the correct product.

Fast delivery: Order processing within 24/48 hours (working days)

Fast delivery: Order processing within 24/48 hours (working days)PROSorb has a unique and exceptional adsorption capacity within the 40 - 60% RH range (see graph), and surpasses all other products sold for this purpose.

PROSorb is able to maintain a stable RH within narrow margins through its ability to both absorb and desorb water vapour; and is provided pre-conditioned to your desired humidity level.

PROSorb also has a longer life span than other silica gels

Free of chlorides: PROSorb contains no lithium chloride, as some other products do (lithium chloride is a chemical - a salt, potentially harmful to many metals. This salt can be transferred to metals in dust or by human touch).PROSorb consists of 97% SiO2 und 3% Al2O3.

Low abrasion: PROSorb beads produce less dust than other silica gels (abrasion< 0.05 weight-% according to MIL-D).

High bulk density: 1 kg PROSorb only needs a volume of ca. 1.5 l (much less than some other silica gels).

Long term stability: PROSorb maintains its adsorption capacity longer than other products. After 10 years we found adsorption capacity of PRO SORB to have decreased by around 20%. In other words: PRO SORB conditioned to 50% RH and maintained at constant weight (e.g. sealed in an aluminium bag) would increase its conditioning by around 0,8 - 1 % RH per year (experimental values after 5 and 10 years). Values might depend on ambient conditions.

Economical: PROSorb is much cheaper than the other products sold for the same purpose.

Temperature dependency: PROSorb is conditioned in relation to temperature. PROSorb reacts in the same way organic materials do. Therefore there will be no, or little, transfer of water vapour between organic materials andPROSorb if the temperature changes. Under fluctuating temperatures, this property protects wooden objects and other organic materials from swelling or shrinking: The conditioning indicated on the labels refers to 20°C. At 10°C the conditioning of the cassettes will be around 1 – 1.5% RH lower, at 30°C around 1 – 1.5% RH higher.

The amount of PRO SORB required depends on various factors, including the airtightness of the display case and the surrounding climate. Since each situation is unique, it is not possible to provide general guidelines. It is recommended to start with 2-4 kg of PRO SORB per cubic meter of display case volume and to continuously monitor the relative humidity (RH) with a hygrometer in each case.

Guideline values:

Dimensions: L 335 mm, W 110 mm, H 24 mm. Content: 500 g beads. One or more cassettes per 0.7 cubic metre of air volume are required, depending on circumstances of application.

Further technical data

Bulk density ca. 0.7 kg/l

Pore volume ca. 0.5 ml/g

Breaking strength over 200 N

Internal surface area ca. 750 m2/g

Specific References